Dynamic blocks have always been a bit of a one-way street in BricsCAD. You could use them, stretch them, flip them, and switch their visibility states, but only if someone else had defined that behavior first. The moment you wanted to change the logic behind the block, you hit a wall. BricsCAD V26 removes that wall.

It’s now possible to create and edit dynamic blocks directly in BricsCAD. So let’s dive into how these blocks behave when exchanged with AutoCAD® and why the feature currently lives in experimental mode.

One important note upfront: dynamic block creation and editing is not currently available in the United States. It is available everywhere else.

From “read-only” to fully editable

Before V26, BricsCAD could only interpret dynamic blocks that were originally created in AutoCAD®. You could stretch them, rotate them, or switch visibility states, but you could not change the block definition itself. If you tried, BricsCAD would offer to convert the block into a parametric one instead.

When experimental mode is enabled, BricsCAD V26 lets you create and edit dynamic blocks natively. You are no longer limited to whatever logic was embedded elsewhere.

Experimental mode, on purpose

Dynamic block creation and editing is still marked as experimental. Not because it is unstable, but because the feature set is not yet complete. We’re keen to gather feedback from real users and refine how the tools evolve.

You can enable experimental mode from the start page, from settings, or directly from the command line. All three methods change the same system variable. A restart is required before the change takes effect.

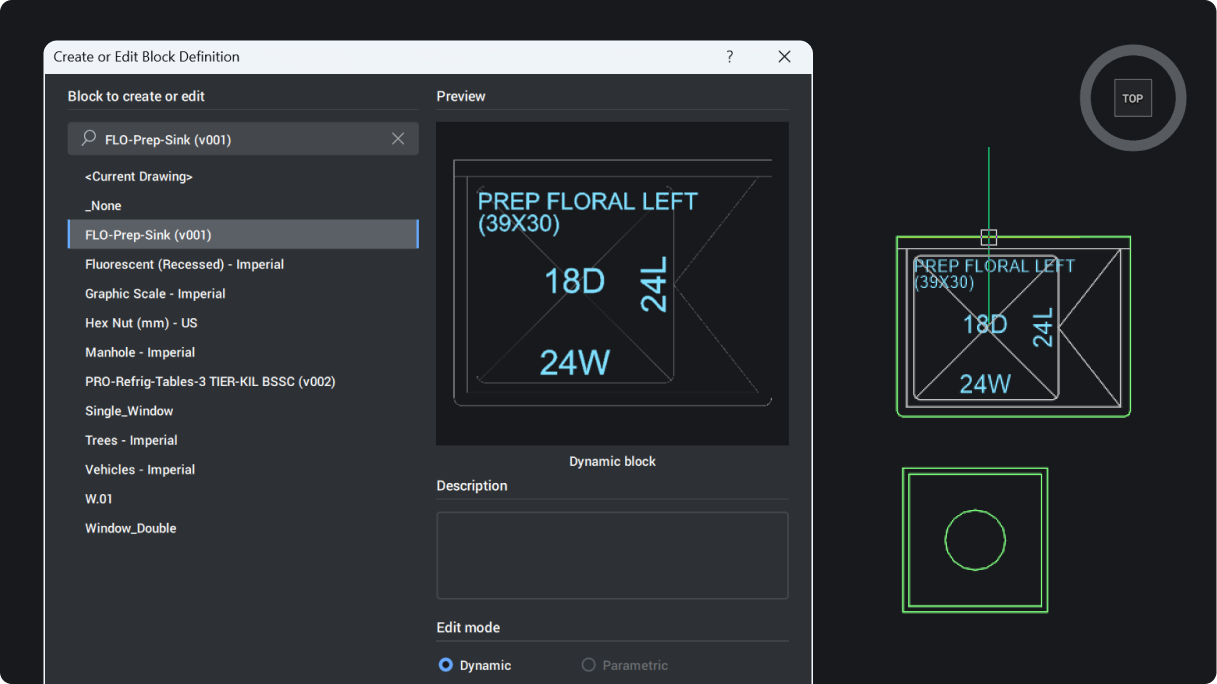

Once enabled, BricsCAD recognizes three block types: traditional static blocks, parametric blocks (2D or 3D), and dynamic blocks, which are always 2D. The software automatically switches you into the correct edit environment based on the block type you select.

Building a dynamic block from scratch

To see what’s possible in BricsCAD V26, consider a simple block that needs to change both width and height. You start with a static base that contains the geometry for both width variants. The first step is to define when each version should appear. Two visibility states are created, one for each width, and the relevant geometry is assigned to each state so only the correct version is shown at a time.

Next, a linear parameter is added to control the height, followed by a stretch action that moves the top plate. The parameter is renamed in the properties panel to make its purpose clear.

At this point, the block works, but it’s too flexible. Any height value is allowed. To limit this, a block table is added. The table links width and height and defines which combinations are valid, so the block only allows approved sizes.

Once the table is made visible in all states, the block behaves as intended: width switches cleanly, height stretches within limits, and the logic remains intact when the drawing is opened in AutoCAD®.

Round-tripping with AutoCAD®

When a drawing is opened in AutoCAD®, the dynamic block behaves the same way. Visibility states, stretch behavior, and the block table are all preserved. This confirms that dynamic blocks created in BricsCAD V26 round-trip cleanly between platforms.

Editing an existing dynamic block

It is also possible to extend a block that already contains predefined sizes. A window block includes a list of valid heights. By editing the parameter’s value set and adding new numbers, the block immediately supports additional sizes. No redraw is required. The logic updates in place.

What's supported today

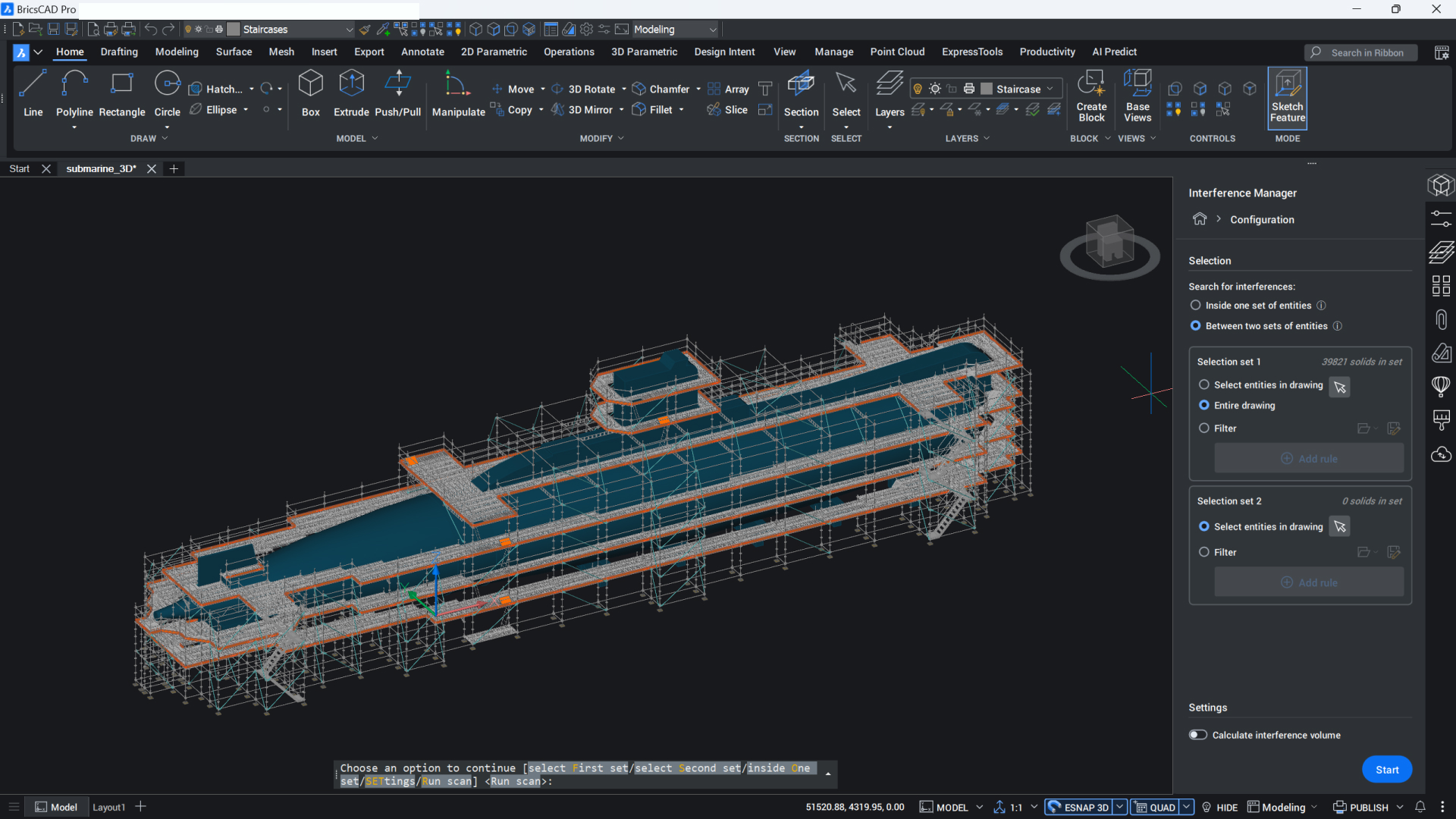

V26 supports the core building blocks of dynamic behavior: visibility states, parameters, actions, block tables, and live testing from inside the editor. You can define how geometry changes, restrict valid values, and verify everything before saving.

Some features are still read-only. Constraint parameters and AutoCAD® lookup tables can be used, but not edited. And again, dynamic block creation and editing is not yet available in the United States.

Need assistance?

If you run into issues, you can file a support request directly from the start page. Choose Dynamic Blocks as the category, describe what you expected to happen, what actually happened, and attach your drawing. Videos can be added as well. Your data is treated as confidential unless you explicitly allow sharing.

Dynamic blocks in BricsCAD have moved from “usable” to “editable.” With V26, you are no longer locked into definitions created elsewhere. You can build, refine, and control block behavior directly while helping shape where the feature goes next.

If you’re based outside the United States, you can start creating and editing dynamic blocks today. BricsCAD V26 is available for download now.