Deep in the heart of Washington, around 40 km (25 mi) from Seattle, is TreeHouse Point, located just outside of Fall City. A resort that proves tree houses aren't just for children. Looking at images of the resort you can't help but get swept away to innocent, childhood days spent climbing trees.

The resort is owned and run by Pete and Judy Nelson. Pete Nelson built his first adult tree house while he was still at college. He says he learned a lot from that experience.

That first treehouse taught me a lot. For instance, I learned that Installing a heavy brick chimney in a treehouse isn't the best idea.

The tree houses

The first tree house was completed in 2006. There are currently 6 tree houses with plans to build a 7th, wheelchair accessible one. Each tree house has its own unique charm and qualities.

Inside the treehouses have armchairs, electrical lighting, curtains, and real beds. The tree houses don't have bathrooms and toilet, aside from the Burl which has its own bathtub. Guest have to use a bathroom located on the ground floor, but it's still more luxurious than a tent.

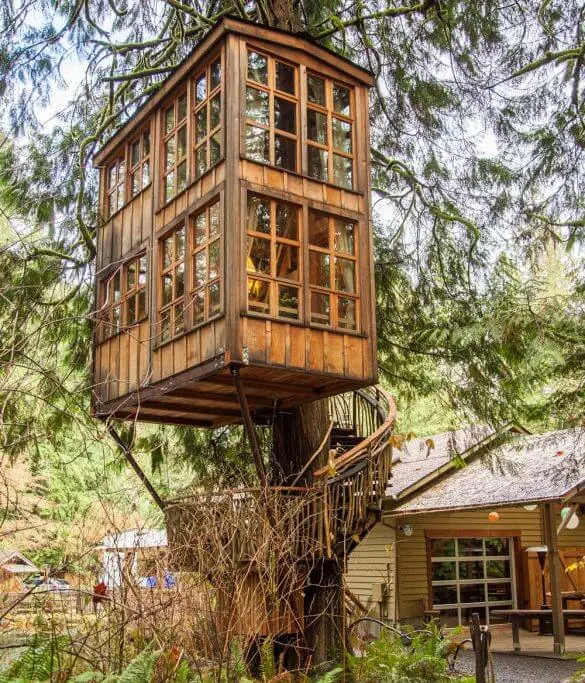

The Bonbibi. Image credit: Pete Nelson/Nelson Treehouse

You can stay the night but you have to be friendly. The tree houses only have twin beds, aside from one: the Upper Pond treehouse which can sleep up to 4 people.

Sustainability

Trillium. Image credit: Pete Nelson/Nelson Treehouse

Like any good tree hugger, Pete Nelson understands that sustainability and minimizing damage to the tree is important.

The wood used to make the tree houses is sustainable and locally sourced. Reclaimed wood is used for the bulk of the tree house structure. When reclaimed wood isn't possible they use locally sourced wood. Douglas Fir is used because over time it develops a deep honey colored patina and is commonly used for the interior. Western red cedar is also frequently used. Chosen as it's naturally resistant to rot due to its high tannin content. Both grow locally.

Temple Treehouse Under construction. Image credit: Pete Nelson/Nelson Treehouse

Every care is taken to ensure that the trees are not damaged. Artificial limbs support the weight of the tree houses. To do this the team has developed specially designed Treehouse Attachment Bolts "TABs". It's a bit like giving the tree a piercing and doesn't cause the tree any long-term damage.

Plans for Temple Treehouse. Image credit: Pete Nelson/Nelson Treehouse

When penetrated in this manner most tree work by sending sap to the point of penetration, to block the entry of pathogens. The tree will then grow "reaction wood" which seals the wound. Interestingly, the type of wood the tree grows at the penetration point contains stronger fibers than the rest of the tree. As the tree grows in girth, it will absorb the TAB and continually strengthening the connection. Cyborg trees!

Trillium under construction. Image credit: Pete Nelson/Nelson Treehouse

Pete Nelson claims that this is a lot less damaging to the tree than alternative methods such as girdling, which involves wrapping chains or ropes around the trunk. This method will cause the tree to "suffocate".

Construction

We've already spoken about adding trees to buildings, but how do you add a building to a tree?

Treehouse Point's nearby carpentry shop prefabricates the tree houses. This takes around 3 weeks. The parts are then packed and sent to the site for assembly. 4-5 carpenters work in the shop and typically 5-6 are on site for the assembly, which takes around 5 -6 weeks. The time varies dependant on the size and complexity of the treehouse.

The Burl

The Burl. Image credit: Pete Nelson/Nelson Treehouse

The most recent and maybe most ambitious of the tree house is a two-story structure known as The Burl, completed in 2013. It's built into a 500-year-old, 1.5m (5ft) diameter, Doug Fir tree and it sits 6m (20ft) above the ground.

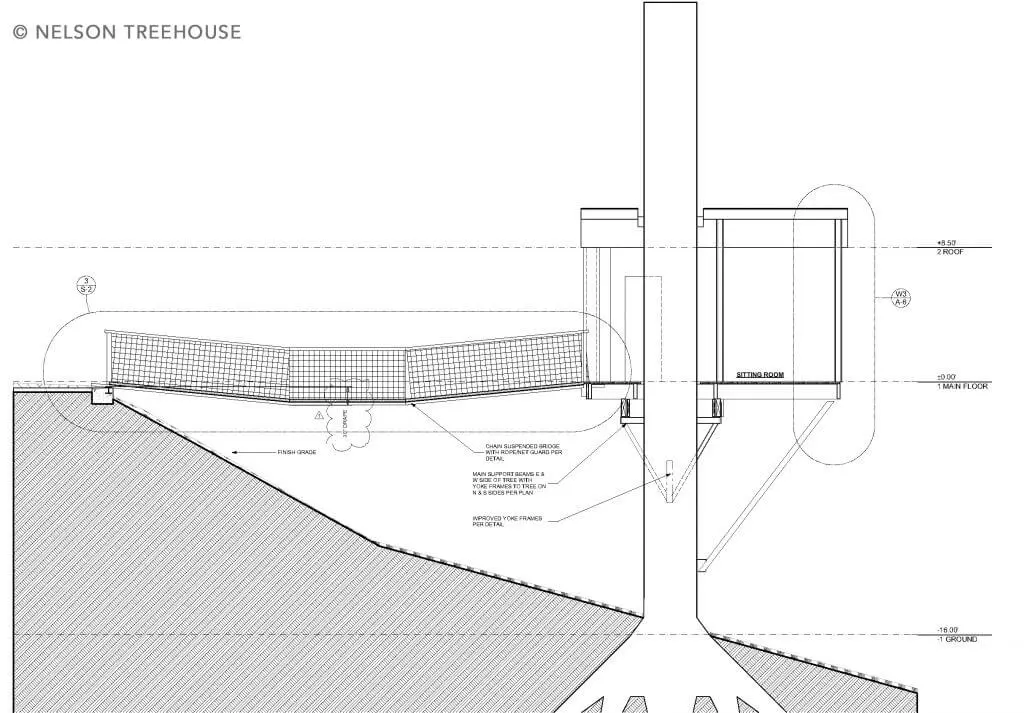

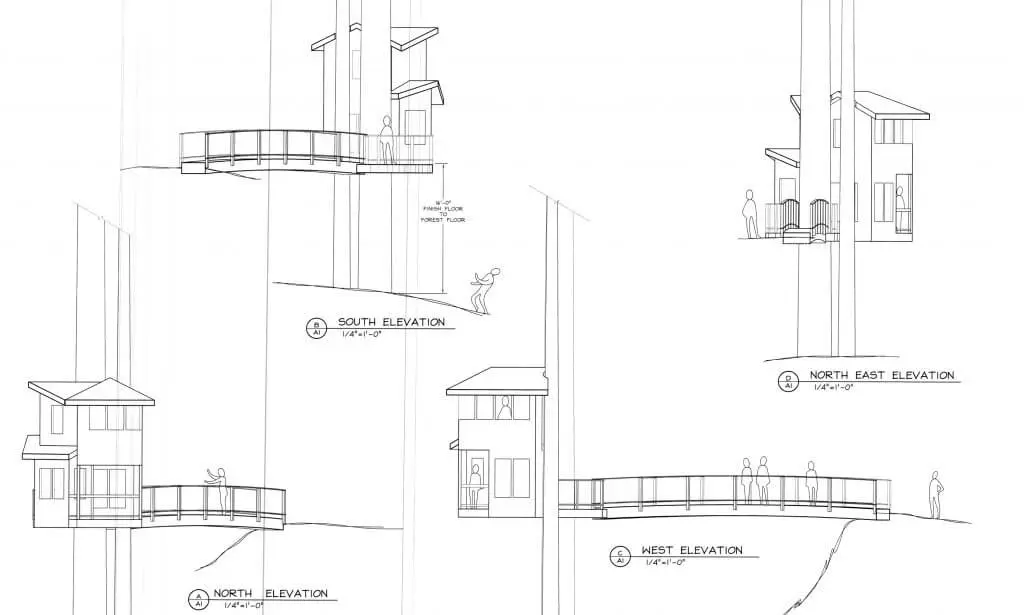

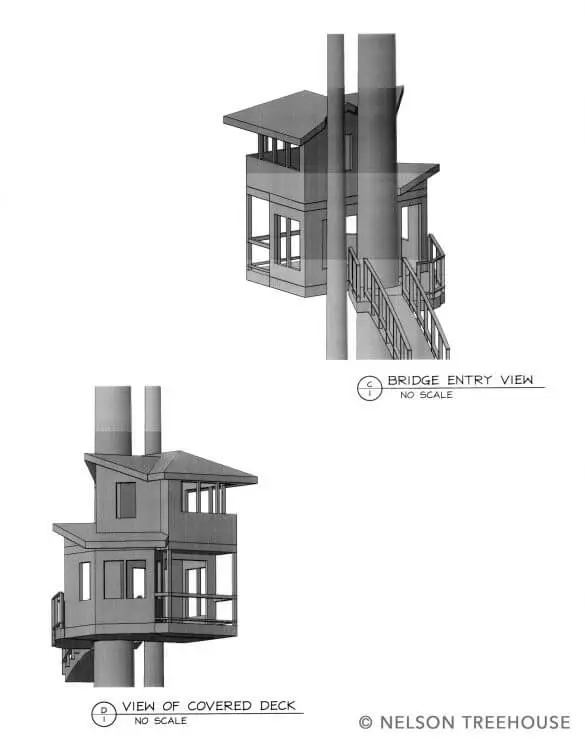

Plans for The Burl. Image credit: Pete Nelson/Nelson Treehouse

You wouldn't know it to look at first sight but the tree houses have a lot of steel in their construction. 9 TABs and a steel undercarriage support The Burl.

The steel undercarriage for The Burl. Image credit: Pete Nelson/Nelson Treehouse

The Bridge

To get to this megastructure you need to walk across a 12m (40 ft) long bridge. This is constructed from 2 steel beams weighing 450 kg (1000 lbs) each and 5.5m (6 yards) of concrete. They chose steel for the construction of the bridge to give a slimmer and more elegant finish. Wood would have needed to be much thicker to achieve the same load-bearing capabilities. The railing is also made from steel and then capped in cedar to give the charming woodland finish.

Engineering structures that fit to trees isn't without its complications. Because the tree bends in the wind the team needed to leave a gap between the tree and the bridge.

Original plans for The Burl. Image credit: Pete Nelson/Nelson Treehouse

The Crow's Nest

Finally, there is the crow's nest, nestled into the top of the tree and, at around 60 m (200 ft) from the ground it's not for the faint-hearted. You need to scale a ladder to reach it. The reward to people that do manage to get to the top are stunning views of the valley. The ladder itself was constructed in sections. Each section needed to be hand hoisted up and then secured with bolts to the tree. Much like the TABs used to support the main structure, the bolts do not damage the tree in the long-term and care was taken to ensure that the tree had sufficient space between the bark and the ladders to allow it to continue to grow.

If you'd like to learn more about treehouse construction, the family also run Nelson Treehouse, where they teach others how to make their own tree houses.

What's next

They have a second site in Texas (Treehouse Utopia) which currently has 4 tree houses and plans are underway for a third resort, run by Pete and Judy's son Charlie. It will also be in Washington.

Fancy designing your own treehouse?

Easy to try, easy to buy, easy to own. That's BricsCAD®. Try all of our products, for free for 30 days at www.bricsys.com. Freedom of choice, plus perpetual (permanent) product licenses that work with all languages, in all places. You'll love what we've built for you with the BricsCAD V19 product family.

TreeHouse Point

TreeHouse Point is located in Washington state. There are currently 6 tree houses where you can spend the night. Specially designed artificial, steel limbs (TABs) support the weight of the tree houses. It's a bit like giving the tree a piercing and doesn't cause the tree any long-term damage. The wood used to make the tree houses is sustainable and locally sourced. The tree houses also have a lot of steel to their construction.