Plataforma CAD basada en DWG

para diseño mecánico

CAD 2D y 3D profesional y familiar basado en DWG para diseño mecánico y dibujo.

Precio a partir de USD 1 000/año

* Prueba gratuita de 30 días, sin tarjeta de crédito.

CONJUNTOS DE HERRAMIENTAS INCLUIDOS

Herramientas mecánicas

Herramientas mecánicas

Cree ensamblajes en 3D y documentación detallada en 2D de los productos fabricados.

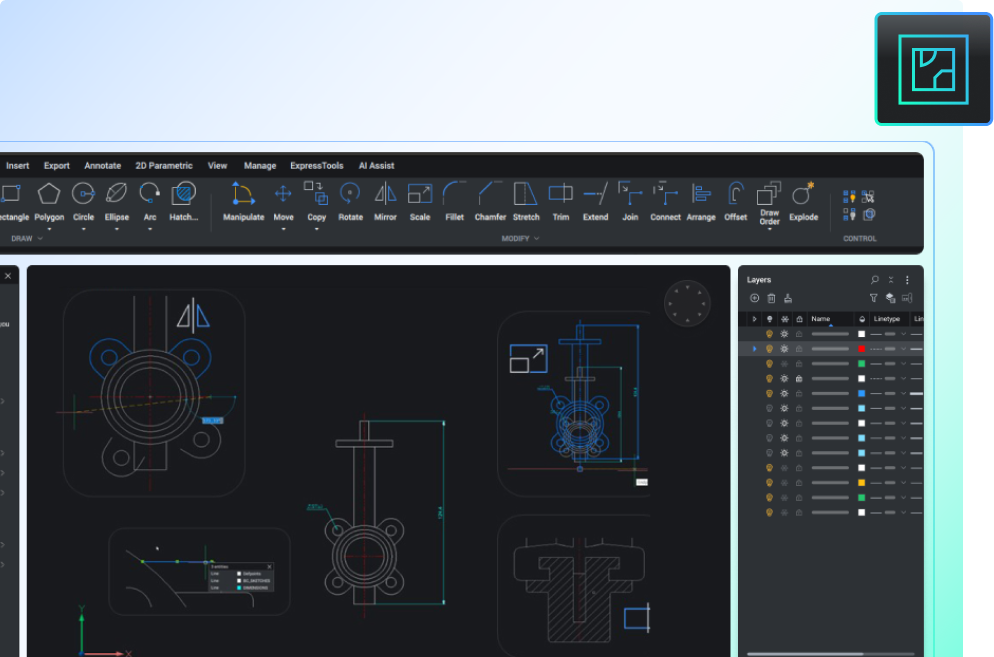

Dibujo 2D

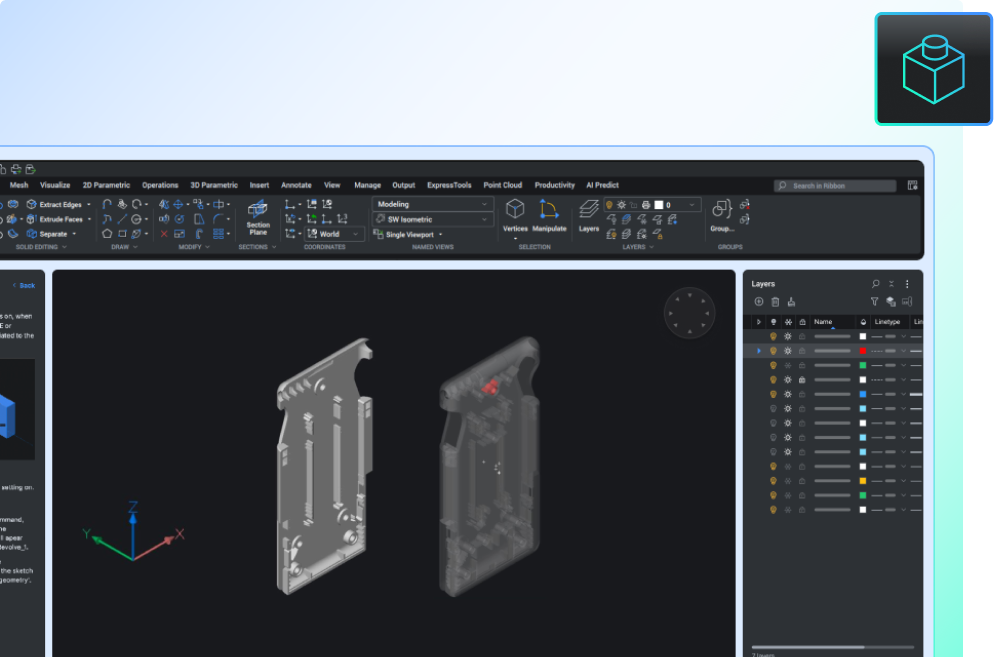

Modelado 3D

BENEFICIOS

Creación acelerada de materiales de producción completos y precisos

Para la creación de ensamblajes en 3D y documentación detallada en 2D de productos fabricados.

Totalmente compatible con el DWG estándar de la industria

Abra, edite y reutilice fácilmente metadatos y características en dibujos CAD heredados, como listas de piezas y referencias, símbolos y anotaciones.

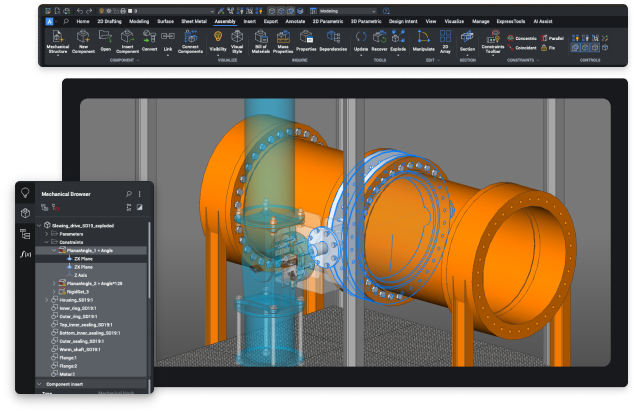

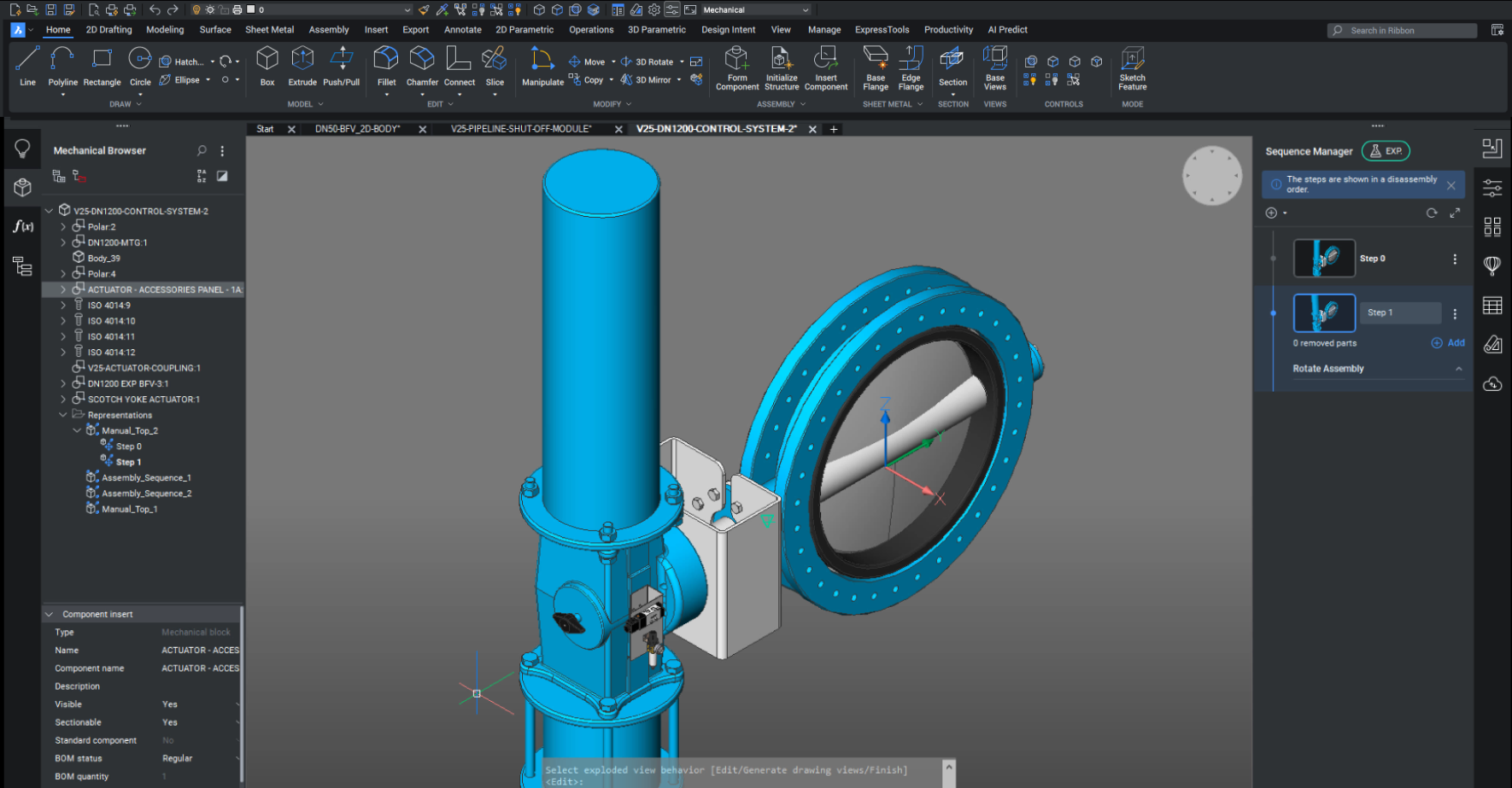

Navegador Mecánico

Visualice y modifique rápidamente las propiedades paramétricas de piezas mecánicas y ensamblajes desde un panel central.

30000+ parametrycznych części standardowych

Construya a partir de una biblioteca de 30,000 componentes mecánicos estándar de 800+ tipos diferentes, todos con parámetros personalizables.

Diseño de montaje ascendente y descendente

Cree jerarquías complejas de piezas y subensamblajes utilizando métodos de diseño de abajo hacia arriba o de arriba hacia abajo.

CAPACIDADES

¿Qué se puede hacer con BricsCAD Mechanical?

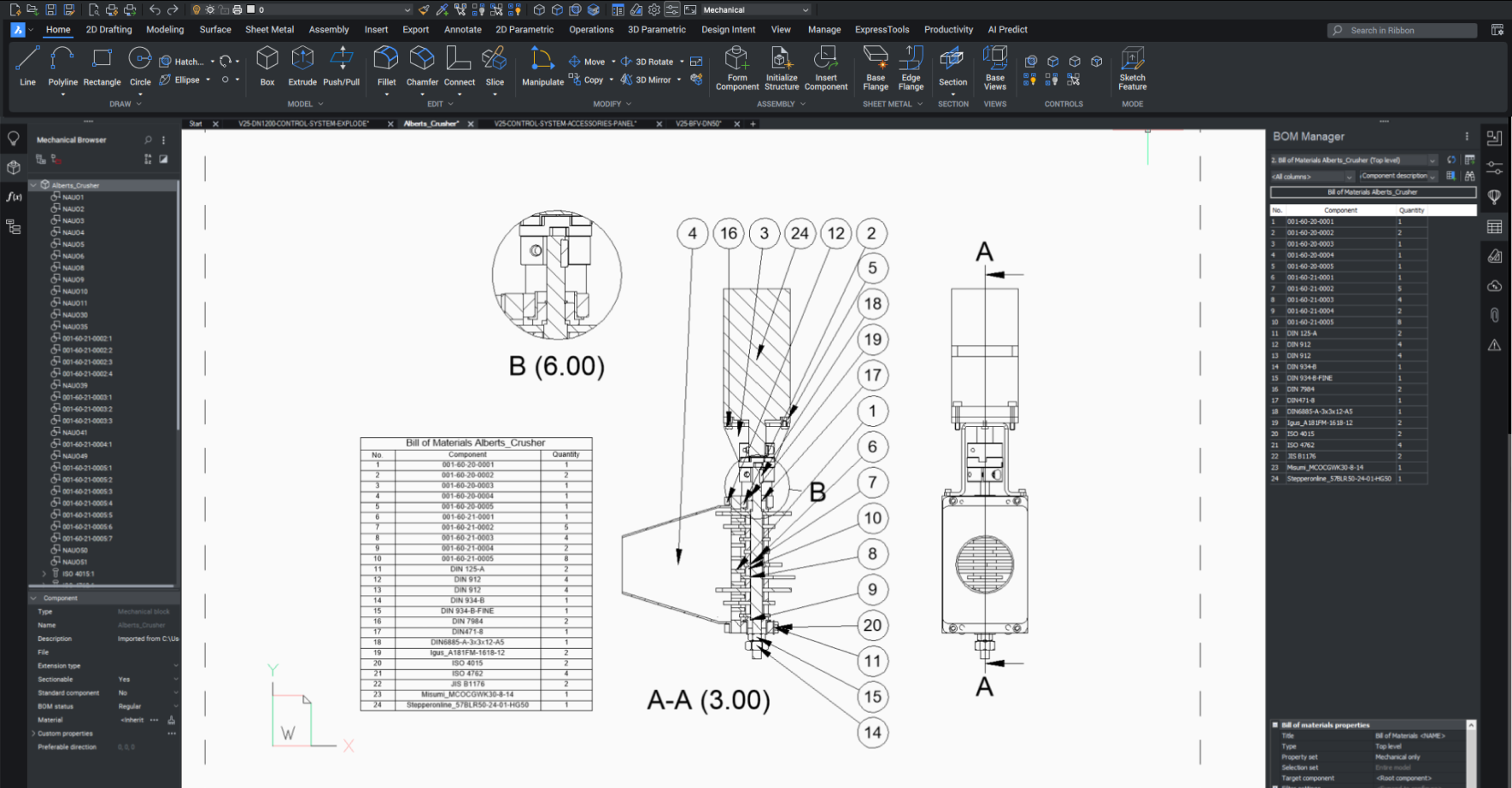

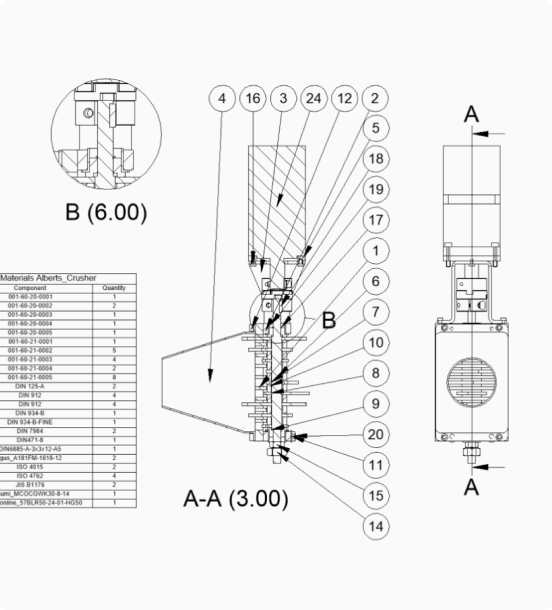

Generar listas de materiales enteramente asociativas:

Cree listas de materiales y listas de piezas automáticamente utilizando los datos de referencia de bloques y piezas.

Conversión automática de entidades 3D en chapa metálica

Traducir modelos 3D a documentación 2D

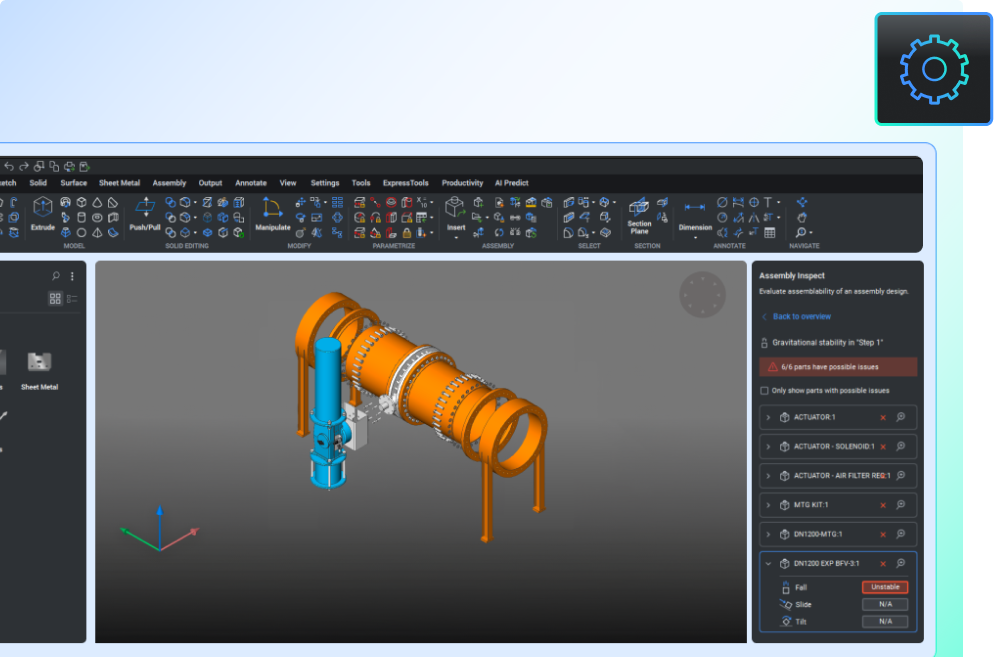

Kit de herramientas de inspección de ensamblaje

AÑADIR

Comunicador para BricsCAD

Importación/exportación de CAD 3D de alta fidelidad

Importe sin problemas modelos de otras herramientas CAD importantes con este complemento

COMPRAR BRICSCAD

Todo nuestro software CAD

CLIENTES

Empresas líderes confían en Bricsys

30 días de prueba